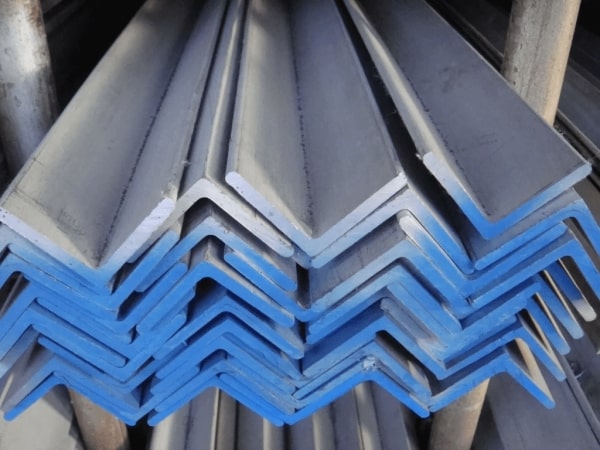

Whenever we are planning to construct a building or manufacture raw materials our prime concern should be offering the best material. There are endless materials that claim to be superior but an Angle Bar is the best among all of them. It comes in L shape and different types of shapes and for this reason it stands out in the crowd for offering numerous benefits.

From providing superior structural integrity to longevity this material is one of the essential components. We are quite sure that all of you are keen to know more about this crucial construction element. Our today’s blog is all about that. We are going to give you the reasons for including an angle bar in your project. So stay with us to fetch them.

The Significance of Angle Bars in Structure –

These angle bars are used in construction works. Along with this you can use these bars for a lot of things. These angle bars can also be used to provide better and longevity to the construction works. Below we have listed some of the reasons to include these highly efficient angle bars in projects. These are as follows.

- High Capacity for Bearing Loads –

This is one of the crucial considerations we must keep in mind while looking for a structural component. The load bearing capacity of this bar is exceptional. Whether you are constructing a residential project or a tower you will never going to have any worries with this material because this bar has a higher level of strength.

To ensure that structures can sustain both vertical and lateral stresses angle bars are frequently employed to support beams and columns and trusses. The L shape of the bar makes it compatible for all the construction related tasks. Besides the Flat Bar also effectively spreads the load across the surface which makes them hold the load and thus it offer superior support to any structure.

- Durability –

It is no wonder that all the stainless steel products offer top notch support to the structure because it is the top most durable product in the world. This L shaped angle bar is made from highly durable galvanized steel and stainless steel which is excellent as a supportive element.

Besides this it is highly resistant to heat and moisture and that is why it can stand in any type of environmental condition. No effect on this material whether it is tremendous hot or humid or snowfall. Apart from that it is highly resistant to corrosion and therefore one can blindly trust this material. Flat bar features for durable structures and this can be included as well after consulting with the architect.

- Customization Options –

The L shaped angle bars are available in wide ranges of sizes and lengths but this can be customized according to the project’s requirement. Different project has their own specific requirement and for this reason one must choose a structural material with greater caution. If one selects the wrong length and thickness of materials then the project should be in danger and it might collapse.

Therefore before selecting a structural component one must consider the specific requirement of the project. Angle bars possess high adaptability which means we can select the proper size and length and thickness according to our project’s needs. Besides this one can cut and weld the bar that is a superior convenience with this material.

- Cost Effectiveness –

Stainless steel is utilized in a variety of projects. It goes without saying that stainless steel products are superiorly durable and that leads them to last for a long time. This material is therefore seen as an affordable choice. It is the most preferred material because of its great durability and resistance to fire and moisture and environmental conditions.

Apart from that it can be cut and welded according to the project’s need which is a huge saving from waste. For this reason Angle Bar has emerged as one of the best options for both residential and business projects.

- Ease of Installation and Lightweight Options –

Whether it is customized or not if it gives trouble during the project work then it must not considered as the best material. But you will not have any complaints with angle bars. It features great when it comes to the installation process. The L shape of the bars enables it to be installed easily in any project.

Apart from that there are welded angle bars that come with holes to fastening bolts and screws. Angle bars are strong; they can also be lightweight and making them easier to handle during installation. This is particularly beneficial for large scale projects where multiple components need to be managed. This function streamlines the installation procedure and drastically cuts down on assembly time.

Common applications of angle bar –

Well the common application of angle can be found in many industries. Along with this you can also use angle for many of your construction related works. However we will know below in which industries you can use them.

- Construction industry –

You can use angle for the construction of many structural components in construction work. Along with this there can be many types of angles. All of them can be used differently in construction work. That is why it can prove to be very helpful in providing strength as well as rigidity to the structures.

- Automotive industry –

The use of angle is not just for one industry. It can be used for different purposes. You can also use them for the automotive industry. They can be used to strengthen the vehicle frame. This can provide a lot of stability and security to the frame.

- Use in manufacturing sector –

You can also use angle bar in the manufacturing sector. It can be very helpful in making machinery and equipment. It is used to give more strength to machinery. This makes the machinery stable and provides its services even under very heavy load.

Conclusion –

Our conversation has come to an end. All of the aforementioned information will undoubtedly be useful to you in obtaining the knowledge you need about an Angle Bar. One must take all the factors into consideration if they are looking for the proper information regarding the material. Apart from that searching for a competent angle bar manufacturer is necessary to confirm the functionality of the material and how much your project will require.